Essential Tools and Techniques for Sheet Metal Working

By:Admin

Sheet metal working is a vital process in the manufacturing industry, and it plays a crucial role in the production of a wide range of products. From automotive parts to household appliances, sheet metal working is essential for creating the metal components that go into these items. For companies like {}, sheet metal working is an integral part of their manufacturing process, allowing them to produce high-quality products for their customers.

Established in 1990, {} has been a leading manufacturer in the sheet metal industry for over three decades. They specialize in the custom fabrication of precision sheet metal components and assemblies for a variety of industries, including aerospace, telecommunications, and medical equipment. Their state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce complex and intricate sheet metal parts with precision and efficiency.

The company's expertise in sheet metal working is evident in their commitment to quality and innovation. They utilize advanced CAD/CAM software to design and engineer their products, ensuring accuracy and precision in every component they produce. Additionally, their team of skilled technicians and engineers are dedicated to delivering superior craftsmanship and attention to detail in every project they undertake.

One of the key aspects of {}'s sheet metal working capabilities is their proficiency in various fabrication techniques. From laser cutting and punching to forming and welding, they have the capability to handle a wide range of materials, including stainless steel, aluminum, and copper. This versatility allows them to meet the diverse needs of their clients and provide custom solutions for their specific requirements.

In addition to their technical expertise, {} places a strong emphasis on sustainability and environmental responsibility in their sheet metal working processes. They are committed to reducing waste and energy consumption in their manufacturing operations and employ eco-friendly practices wherever possible. This dedication to sustainability not only benefits the environment but also enhances the company's reputation as a responsible and ethical manufacturer.

The significance of sheet metal working in the manufacturing industry cannot be overstated, and companies like {} play a vital role in delivering high-quality components to their customers. Whether it's producing intricate parts for the aerospace industry or fabricating durable enclosures for telecommunications equipment, sheet metal working is essential for creating reliable and efficient products.

Looking ahead, {} remains committed to pushing the boundaries of sheet metal working and embracing new technologies and processes to enhance their capabilities. They are constantly investing in research and development to stay at the forefront of the industry and continue to deliver innovative solutions to their clients.

In conclusion, sheet metal working is a critical component of the manufacturing process, and companies like {} are leading the way in delivering superior quality and precision in the production of sheet metal components. With their dedication to quality, innovation, and sustainability, {} continues to be a trusted partner for businesses seeking reliable and efficient sheet metal solutions.

Company News & Blog

High-Quality CNC Machined Aluminum Parts for Precision Engineering

[Company Name] specializes in providing high-quality CNC machined aluminum parts for a wide range of industries. The company has established itself as a leader in the manufacturing of precision components, and their expertise in aluminum machining has set them apart from their competitors. With a focus on the latest technology and a commitment to excellence, [Company Name] has become a trusted supplier for companies looking for reliable and efficient aluminum parts.The demand for CNC machined aluminum parts has been growing steadily in recent years, as industries such as aerospace, automotive, and electronics require components that are lightweight, durable, and precise. Aluminum has become the material of choice for many of these applications, and [Company Name] has positioned itself as a top provider of CNC machined aluminum parts to meet this demand.The company's state-of-the-art manufacturing facilities are equipped with the latest CNC machining technology, allowing them to produce complex, high-precision aluminum parts with tight tolerances. The team of skilled engineers and technicians at [Company Name] is dedicated to ensuring that every part meets the highest standards of quality and performance.In addition to their advanced manufacturing capabilities, [Company Name] also places a strong emphasis on customer service and satisfaction. They work closely with their clients to understand their specific needs and requirements, and then tailor their manufacturing processes to deliver custom aluminum parts that meet or exceed expectations. This commitment to customer-centric solutions has solidified [Company Name]'s reputation as a trusted partner in the industry.One of the key advantages of choosing CNC machined aluminum parts from [Company Name] is the superior strength-to-weight ratio that aluminum offers. This makes it an ideal material for applications where weight is a critical factor, such as in the aerospace and automotive industries. Additionally, aluminum is highly resistant to corrosion, which adds to its durability and longevity.Furthermore, [Company Name] uses only the highest quality aluminum materials to ensure that their parts are strong, reliable, and can withstand the demands of various applications. Their rigorous quality control processes guarantee that every part meets the strictest industry standards and specifications. This level of precision and attention to detail has earned [Company Name] a reputation for consistently delivering top-quality CNC machined aluminum parts.Another advantage of working with [Company Name] is their ability to provide quick turnaround times without compromising on quality. The company understands the importance of meeting deadlines and strives to deliver parts within the agreed-upon timeframe. Whether it's a small batch of custom parts or a large production run, [Company Name] has the capacity and expertise to fulfill orders efficiently and effectively.With a strong focus on innovation and continuous improvement, [Company Name] is well-equipped to meet the evolving needs of the industry. By staying at the forefront of technological advancements and investing in the latest CNC machining equipment, they are able to offer cutting-edge solutions for complex aluminum components.In conclusion, [Company Name] is a leading provider of CNC machined aluminum parts, with a strong track record of delivering high-quality, precision-engineered components to a diverse range of industries. Their commitment to excellence, customer-oriented approach, and expertise in aluminum machining make them a reliable partner for companies seeking top-tier aluminum parts. As the demand for CNC machined aluminum parts continues to grow, [Company Name] is well-positioned to meet the needs of the industry and continue to be a trusted supplier for years to come.

Revolutionizing Manufacturing: 3D Printing Services in China

China 3D Printing Service, commonly known as C3PS, is revolutionizing the manufacturing industry with its state-of-the-art technology and high-quality 3D printing services. The company has been making headlines for its innovative approach to additive manufacturing and its commitment to providing exceptional products to its clients. With a strong focus on sustainability and efficiency, C3PS is leading the way in the 3D printing industry in China and beyond.C3PS utilizes the latest 3D printing technology to create intricate and precise parts for a wide range of industries. From aerospace to automotive, healthcare to consumer goods, C3PS can handle a variety of projects with its advanced 3D printing capabilities. The company prides itself on its ability to produce complex designs with quick turnaround times, making it a top choice for businesses looking for high-quality 3D printing services.One of the key factors that sets C3PS apart from its competitors is its dedication to sustainability. The company is committed to reducing waste and minimizing its environmental impact by using eco-friendly materials and processes. By implementing sustainable practices in its manufacturing processes, C3PS is not only contributing to a cleaner and greener planet but also helping its clients meet their own sustainability goals.In addition to its cutting-edge technology and sustainable practices, C3PS is also known for its exceptional customer service. The company works closely with each client to understand their specific needs and provide tailored solutions to meet their requirements. Whether it's a small prototype or a large-scale production run, C3PS has the expertise and experience to deliver top-quality 3D printed parts on time and within budget.Furthermore, C3PS is constantly investing in research and development to stay ahead of the curve in the 3D printing industry. The company is always exploring new materials, processes, and technologies to improve its capabilities and offer innovative solutions to its clients. With a team of highly skilled engineers and technicians, C3PS is at the forefront of technological advancements in the additive manufacturing sector.As the demand for 3D printing services continues to grow, C3PS is well-positioned to capitalize on this trend and expand its reach in the global market. The company's dedication to quality, sustainability, and customer satisfaction has earned it a solid reputation as a leader in the 3D printing industry. With a strong focus on innovation and continuous improvement, C3PS is poised to remain at the forefront of the additive manufacturing sector for years to come.In conclusion, China 3D Printing Service is a shining example of a company that is pushing the boundaries of technology and sustainability in the manufacturing industry. With its advanced 3D printing capabilities, commitment to sustainability, and exceptional customer service, C3PS is setting a new standard for additive manufacturing. As the company continues to grow and evolve, it is poised to make an even greater impact on the 3D printing industry and solidify its position as a global leader in the field.

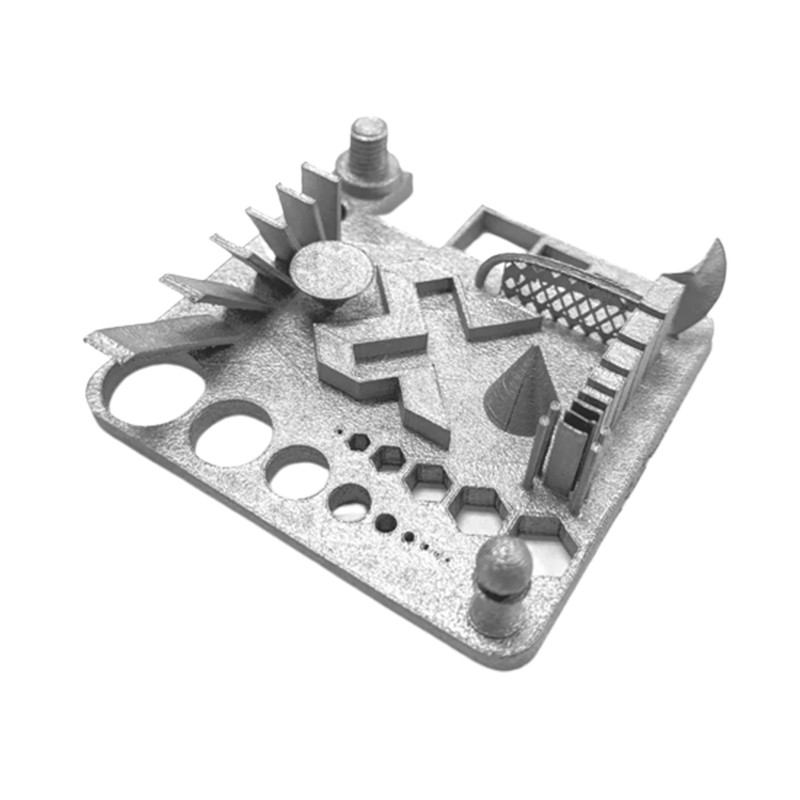

Top 3 Advantages of 3D Printing Metal Parts

Metal 3D printing is revolutionizing the way companies manufacture parts and products, and leading the charge in this cutting-edge technology is [company]. With their advanced metal 3D printing capabilities, [company] is breaking new ground and setting a new standard for precision, quality, and efficiency in the manufacturing industry.Utilizing state-of-the-art metal 3D printing technology, [company] is able to create complex metal parts with unprecedented precision and intricacy. This technology allows for the production of parts that were previously thought to be impossible to manufacture, opening up a world of new possibilities for engineers and designers. From intricate aerospace components to durable automotive parts, [company] is at the forefront of creating high-quality metal parts that meet the strictest industry standards.One of the key advantages of metal 3D printing is the ability to produce parts with unparalleled precision. Traditional manufacturing methods often result in small imperfections and inconsistencies in metal parts, but with 3D printing, [company] is able to create flawless, high-precision components that meet the exact specifications of their customers. This level of precision is essential in industries such as aerospace and medical, where even the smallest deviation from the intended design can have far-reaching consequences.In addition to precision, metal 3D printing also allows for the creation of highly complex parts that would be extremely difficult, if not impossible, to produce using traditional methods. The ability to create intricate lattices, internal structures, and unique geometries gives engineers and designers the freedom to explore new design possibilities and push the boundaries of what is possible in metal manufacturing.[Company]'s metal 3D printing capabilities also offer significant efficiencies in the manufacturing process. By eliminating the need for traditional tooling and machining, [company] is able to reduce lead times and production costs, resulting in faster turnaround times and more cost-effective solutions for their customers. This streamlined manufacturing process also reduces material waste, making metal 3D printing a more sustainable and environmentally friendly option for producing metal parts.As a leader in metal 3D printing, [company] is dedicated to pushing the boundaries of what is possible in metal manufacturing. Their team of skilled engineers and technicians are constantly innovating and developing new techniques to further improve the quality and capabilities of their metal 3D printing technology. By staying at the forefront of this rapidly evolving industry, [company] is able to provide their customers with the most advanced and cutting-edge solutions for their metal manufacturing needs.With their commitment to quality, precision, and innovation, [company] is redefining the metal manufacturing industry with their advanced metal 3D printing capabilities. By leveraging the power of this revolutionary technology, [company] is able to produce high-quality metal parts with unmatched precision and complexity, setting a new standard for the industry. As the demand for metal 3D printed parts continues to grow across a wide range of industries, [company] is well-positioned to lead the way in providing innovative and cost-effective solutions for their customers.

High-Quality CNC Machined Aluminum Parts for Various Industries

In the world of advanced manufacturing, the use of CNC machine aluminum parts has become increasingly popular due to their precision, flexibility, and efficiency. As a leading manufacturer in the industry, {Company Name} has emerged as a primary supplier of high-quality CNC machined aluminum parts for a wide range of applications. With state-of-the-art technology and a commitment to excellence, {Company Name} has positioned itself as a trusted partner for businesses looking to streamline their production processes.CNC machining, or Computer Numerical Control machining, utilizes computer-aided design (CAD) and computer-aided manufacturing (CAM) software to control the movements of the machinery and create complex, bespoke aluminum parts. This process allows for the production of highly accurate and intricate components that meet the exact specifications of the customer.{Company Name} specializes in producing CNC machined aluminum parts for a variety of industries, including aerospace, automotive, electronics, and medical devices. With a team of skilled engineers and machinists, the company has the expertise to handle projects of any scale and complexity. Whether it's a prototype for a new product or a large production run, {Company Name} can deliver the desired results with precision and efficiency.One of the key advantages of CNC machining aluminum parts is the material's excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. These properties make it an ideal choice for a wide range of applications, from precision components in aircraft to heat sinks in electronic devices. With its high machinability, aluminum allows for fast and efficient manufacturing, reducing lead times and overall production costs.{Company Name} prides itself on its ability to deliver high-quality CNC machined aluminum parts that meet the stringent requirements of its customers. By leveraging advanced CNC technology and adhering to strict quality control processes, the company ensures that every part meets the highest standards of accuracy and performance. This commitment to quality has earned {Company Name} a reputation as a reliable and trusted supplier within the industry.In addition to its CNC machining capabilities, {Company Name} offers a range of value-added services to support its customers' needs. These services include finishing processes such as anodizing, powder coating, and assembly, allowing for a streamlined production process and a one-stop solution for customers.With a focus on innovation and continuous improvement, {Company Name} remains at the forefront of the CNC machining industry. The company invests in the latest technology and machinery, as well as ongoing training for its employees, to ensure that it can meet the evolving demands of its customers and stay ahead of the competition.As the demand for precision-engineered aluminum parts continues to grow across various industries, {Company Name} is well-positioned to meet this demand with its expertise and capabilities in CNC machining. The company's dedication to quality, precision, and customer satisfaction sets it apart as a leader in the manufacturing of CNC machined aluminum parts.In conclusion, the use of CNC machine aluminum parts has become increasingly important in advanced manufacturing, and {Company Name} has established itself as a leading supplier of high-quality, precision-engineered parts. With its state-of-the-art technology, skilled team, and commitment to excellence, {Company Name} is well-equipped to meet the evolving needs of its customers and provide innovative solutions for their CNC machining requirements.

Guide to Injection Moldable Plastics: Benefits, Applications, and Best Practices

Injection Moldable Plastics (IMP) is a leading company in the plastic manufacturing industry, known for its high-quality and innovative products. Specializing in injection moldable plastics, the company has been a key player in providing solutions for a wide range of industries, including automotive, medical, consumer goods, and electronics.With a strong focus on research and development, IMP has continually pushed the boundaries of what is possible with injection moldable plastics. The company's team of experts is dedicated to creating new and improved materials that meet the ever-evolving needs of their customers.One of the key factors that set IMP apart from its competitors is the company's commitment to sustainable and environmentally friendly manufacturing practices. IMP has invested heavily in developing plastic materials that are recyclable and biodegradable, reducing the environmental impact of plastic waste.In addition to its commitment to sustainability, IMP is also dedicated to producing plastics that are safe and non-toxic. The company adheres to strict quality control measures to ensure that its products meet the highest safety standards, making them suitable for use in a wide range of applications, including food packaging and medical devices.Furthermore, IMP's dedication to innovation has led to the development of plastics with advanced properties, such as high tensile strength, heat resistance, and chemical resistance. These advanced materials have opened up new possibilities for product design and have allowed customers to create products with longer lifespan and improved performance.One of the key advantages of using injection moldable plastics from IMP is the flexibility they offer in product design and manufacturing. The company's materials can be molded into virtually any shape and size, allowing for complex and intricate designs that would not be possible with traditional materials. This versatility has made IMP's plastics a popular choice for companies looking to create unique and distinctive products.In recent news, IMP has announced the launch of a new line of injection moldable plastics that have been specifically designed for use in the automotive industry. These materials have been engineered to meet the rigorous demands of the automotive sector, including high impact resistance, temperature resistance, and long-term durability. With this new product line, IMP aims to further expand its presence in the automotive market and provide solutions for the industry's evolving needs.To ensure that its customers have access to the latest and most advanced plastic materials, IMP has also established strong partnerships with leading suppliers of raw materials and additives. These partnerships allow the company to stay at the forefront of material innovation and offer its customers the best possible solutions for their specific requirements.As part of its commitment to customer satisfaction, IMP provides comprehensive technical support and guidance to help its clients choose the right plastic materials for their applications. The company's team of experts is available to provide assistance with material selection, product design, and manufacturing processes, ensuring that customers can achieve the best results with IMP's plastics.Looking to the future, IMP is committed to continued innovation and the development of new and improved plastics that push the boundaries of what is possible in the industry. With a focus on sustainability, safety, and performance, the company aims to be a leading provider of injection moldable plastics for a wide range of applications, and to contribute to a more sustainable and environmentally friendly future.

Top Level Injection Production: What You Need to Know

Injection Production has been at the forefront of the manufacturing industry for over a decade, providing high-quality injection molded products for a wide range of applications. With state-of-the-art facilities and a dedicated team of professionals, Injection Production has become a leader in the industry, setting new standards for quality and innovation.The company specializes in the production of injection molded parts for various industries, including automotive, medical, consumer products, and electronics. Their products are known for their precision, durability, and reliability, making them the go-to choice for many leading companies around the world.Injection Production's success can be attributed to their commitment to excellence and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and offer cutting-edge solutions to their customers' needs. This dedication to innovation has earned Injection Production a reputation for being a trusted partner in the industry.In addition to their commitment to quality, Injection Production also places a strong emphasis on sustainability and environmental responsibility. The company has implemented a range of eco-friendly initiatives to minimize their impact on the environment, including the use of recycled materials and energy-efficient production processes. This commitment to sustainability has not only helped Injection Production reduce their carbon footprint but has also positioned them as a leader in environmentally responsible manufacturing.Recently, Injection Production announced the introduction of a new production line that will significantly increase their manufacturing capacity. This state-of-the-art facility will feature the latest technologies and equipment, allowing the company to produce a wider range of injection molded products with even greater precision and efficiency."We are thrilled to announce the expansion of our production capabilities with the addition of our new production line," said the CEO of Injection Production. "This investment represents our commitment to meeting the growing demands of our customers and further solidifying our position as a leader in the industry."The new production line will enable Injection Production to streamline their manufacturing processes and reduce lead times, allowing them to deliver products to their customers faster than ever before. This increased efficiency will also allow the company to take on larger orders and execute complex projects with ease.In addition to expanding their production capacity, Injection Production has also announced plans to enhance their research and development capabilities. The company is investing in cutting-edge technologies and talent to drive innovation and develop new solutions for their customers."Our commitment to innovation is at the core of our business, and we are dedicated to pushing the boundaries of what is possible in injection molding," the CEO added. "By investing in our R&D capabilities, we aim to continue providing our customers with the best products and solutions available in the market."The expansion of Injection Production's production capabilities comes at a time when the demand for injection molded products is on the rise. With industries such as automotive, medical, and consumer products experiencing significant growth, the company is well-positioned to capitalize on these opportunities and further solidify its position as an industry leader.As Injection Production continues to grow and evolve, they remain committed to their core values of quality, innovation, and sustainability. With their new production line and enhanced R&D capabilities, the company is poised for continued success and leadership in the injection molding industry.

The Complete Guide to Plastic Injection Process

Plastic Injection Process Revolutionizes Manufacturing IndustryIn today’s fast-paced and technology-driven world, it’s important for manufacturing companies to stay ahead of the game by implementing the latest technologies and processes. One company that is leading the way in this regard is {}. With over 30 years of experience in the plastic injection industry, {} has established itself as a pioneer in the field, constantly pushing the boundaries of what is possible with plastic injection molding.The plastic injection process is a manufacturing technique for producing parts by injecting molten material into a mold. This process is widely used in the production of a variety of products, including automotive parts, medical devices, and consumer goods. The process is known for its high level of precision, efficiency, and flexibility, making it an ideal choice for a wide range of manufacturing applications.{} has taken the plastic injection process to a whole new level by incorporating the latest advancements in technology and materials. The company utilizes state-of-the-art injection molding machines and has a team of highly skilled engineers and technicians who are experts in their field. This has allowed {} to consistently deliver high-quality, precision-engineered plastic parts to its customers.One of the key advantages of {}’s plastic injection process is its ability to produce complex and intricate parts with ease. The company’s advanced molding machines are capable of creating parts with intricate geometries and tight tolerances, which would be difficult or impossible to achieve using traditional manufacturing methods. This level of precision is particularly important in industries such as automotive and aerospace, where the quality and performance of the parts are crucial.Furthermore, {}’s plastic injection process is highly efficient, with the ability to produce large volumes of parts in a relatively short amount of time. This is particularly beneficial for customers who require high-volume production runs, as it allows them to quickly and cost-effectively meet their manufacturing needs.In addition to its precision and efficiency, {}’s plastic injection process is also environmentally friendly. The company is committed to sustainability and has invested in environmentally friendly materials and processes. {} produces parts using recyclable and biodegradable materials, minimizing the environmental impact of its manufacturing operations.Moreover, {} is dedicated to providing exceptional customer service and support. The company works closely with its customers from the initial design phase through to production, ensuring that their specific requirements are met. {}’s team of experts are on hand to provide technical advice and guidance, helping customers to optimize their designs for the plastic injection process.With its commitment to innovation, precision, efficiency, and sustainability, {} has firmly established itself as a leader in the plastic injection industry. The company’s advanced molding capabilities and dedication to customer satisfaction have set it apart from its competitors. As the demand for high-quality plastic parts continues to grow, {} is well-positioned to meet the needs of its customers and drive the industry forward.In conclusion, the plastic injection process is a critical manufacturing technique that has revolutionized the industry, and {} is at the forefront of this revolution. With its cutting-edge technology, skilled workforce, and dedication to excellence, {} continues to raise the bar for what is possible with plastic injection molding. As the company looks to the future, it is poised to continue leading the way in the industry, delivering innovative solutions and exceptional quality to its customers.

Durable Custom Metal Cases for Electronic Devices

Custom Metal Case Expands Its Offerings to Serve a Wide Range of IndustriesCustom Metal Case, a leading manufacturer of high-quality metal cases, has recently announced its expansion to serve a wider range of industries. With its state-of-the-art manufacturing facilities and a team of experienced engineers, the company is now able to produce custom metal cases for a variety of applications, including industrial equipment, medical devices, and military use.Founded in 2005, Custom Metal Case has built a strong reputation for providing top-quality metal cases that meet the specific needs of its customers. The company's commitment to precision engineering and superior craftsmanship has made it a preferred partner for many leading companies in various industries.The expansion of Custom Metal Case's offerings comes at a time when the demand for custom metal cases is growing across different sectors. As companies seek to protect their valuable equipment and devices, the need for durable and reliable metal cases has become increasingly crucial."We are excited to announce our expansion to serve a wider range of industries," said the CEO of Custom Metal Case. "We have invested heavily in upgrading our manufacturing capabilities and expanding our product offerings to meet the growing demand for custom metal cases. Our team is ready to take on new challenges and deliver innovative solutions for our customers' specific needs."Custom Metal Case's custom metal cases are known for their durability, versatility, and superior protection. The company uses cutting-edge technology and advanced materials to ensure that its metal cases can withstand the harshest conditions and provide maximum protection for the equipment inside.In addition to serving the industrial equipment and medical device industries, Custom Metal Case is now also able to cater to the specific requirements of the military sector. The company has the expertise and precision engineering capabilities to produce custom metal cases that meet the stringent standards of military applications."Our expansion allows us to provide custom metal cases for military use, where reliability and durability are absolutely critical," the CEO added. "We understand the unique challenges and requirements of military applications, and we are fully equipped to deliver metal cases that meet the highest standards of quality and performance."Custom Metal Case's commitment to innovation and excellence has positioned the company as a trusted partner for companies looking for custom metal cases that offer maximum protection and reliability. The company's expansion to serve a wider range of industries will further strengthen its position in the market and enable it to meet the evolving needs of its customers.The company's state-of-the-art manufacturing facilities, combined with its team of experienced engineers and commitment to superior craftsmanship, make Custom Metal Case the go-to choice for businesses that require custom metal cases for their specific applications. As the demand for custom metal cases continues to grow, Custom Metal Case is well-positioned to remain a leader in the industry, providing innovative solutions and top-quality products for its customers.

Rapid Plastic Machining Services: Fast and Efficient Solutions for Your Plastic Needs

Rapid Plastic Machining, a leading provider of high-quality plastic machining and fabrication services, has recently announced the expansion of their operations to meet the growing demand for their services. The company, which has been in the industry for over 20 years, has established itself as a reliable partner for businesses in need of precision plastic components.With state-of-the-art equipment and a team of experienced professionals, Rapid Plastic Machining is capable of delivering top-notch plastic products to a wide range of industries, including aerospace, medical, automotive, and electronics. Their extensive experience and dedication to quality have earned them a reputation as a trusted and dependable supplier of plastic components.The expansion of their operations comes as a response to the increasing demand for their services. The company has seen a surge in orders from both existing and new clients, prompting them to enhance their production capabilities to ensure that they can meet the needs of their customers in a timely manner. By increasing their capacity, Rapid Plastic Machining will be able to take on larger projects and accommodate more clients, further solidifying their position as a leader in the plastic machining industry.In addition to expanding their production capabilities, the company has also made advancements in their technology and processes to further improve efficiency and precision. By investing in the latest machining equipment and implementing advanced techniques, Rapid Plastic Machining is able to offer even higher quality products with shorter lead times. This commitment to innovation and continuous improvement sets them apart from their competitors and ensures that their clients receive the best possible solutions for their plastic machining needs.Furthermore, the company is dedicated to providing exceptional customer service, working closely with their clients to understand their unique requirements and deliver customized solutions that meet their specific needs. Their team of experts is always available to provide guidance and support, from the initial design phase to the final delivery of the product. This personalized approach has earned them the trust and loyalty of their clients, who continue to rely on Rapid Plastic Machining for all their plastic component needs.As part of their expansion, Rapid Plastic Machining has also increased their focus on sustainability and environmental responsibility. They have implemented eco-friendly practices in their operations, such as recycling and minimizing waste, to reduce their environmental footprint and contribute to a healthier planet. By prioritizing sustainability, the company is not only making a positive impact on the environment but also aligning with the values of their clients who seek responsible and ethical partners for their supply chain.Rapid Plastic Machining's expansion is a testament to their dedication to excellence and their commitment to meeting the evolving needs of their clients. With their enhanced production capabilities, advanced technology, and unwavering dedication to customer satisfaction, the company is well-positioned to continue leading the plastic machining industry and providing innovative solutions to businesses across various sectors. Their reputation for quality, reliability, and exceptional service sets them apart as a preferred partner for all plastic machining and fabrication needs.

Innovative Medical Device Prototype Revealed in Latest News

Medical Device Prototype: Revolutionizing HealthcareMedical technology has advanced by leaps and bounds in recent years, with new devices and innovations consistently being introduced to improve patient care and outcomes. One such advancement is the development of a groundbreaking medical device prototype by the innovative team at {Company}, a leading medical technology company.{Company} is a global leader in medical device development, specializing in cutting-edge technology that aims to improve the lives of patients and healthcare professionals. With a strong focus on research and development, {Company} has consistently delivered innovative solutions that address the most pressing needs in the healthcare industry.The latest achievement from {Company} is a medical device prototype that is set to revolutionize the way certain medical conditions are diagnosed and treated. The prototype, which is currently in the testing phase, has the potential to significantly improve patient outcomes and streamline the diagnostic process for healthcare providers.One of the most striking features of the medical device prototype is its ability to provide accurate and real-time data, allowing healthcare professionals to make informed decisions quickly and effectively. This can be especially crucial in emergency situations where time is of the essence, and quick diagnosis and intervention can be life-saving.Additionally, the prototype is designed with patient comfort and convenience in mind. The team at {Company} has prioritized the development of a device that is user-friendly and non-invasive, ensuring that patients feel at ease during the diagnostic and treatment process.The potential applications for the medical device prototype are wide-reaching, with implications for a variety of medical specialties. From cardiology to neurology, the device has the potential to enhance clinical practice and improve patient care across the board.In addition to its remarkable functionality, the prototype also represents a significant leap forward in terms of design and engineering. The team at {Company} has worked tirelessly to ensure that the device is not only highly effective but also practical and durable, making it a valuable asset for healthcare facilities of all sizes.The development of the medical device prototype is a testament to {Company}'s commitment to pushing the boundaries of medical technology and driving innovation in healthcare. With a team of dedicated professionals and a culture of continuous improvement, {Company} has positioned itself as a leader in the field of medical device development, consistently delivering solutions that make a real difference in the lives of patients and healthcare providers.Looking ahead, {Company} is poised to continue its trajectory of success, with an impressive pipeline of new projects and innovations on the horizon. The medical device prototype is just one example of the company's dedication to advancing healthcare through technology, and there is no doubt that {Company} will continue to make significant contributions to the field in the years to come.As the medical device prototype moves closer to commercialization, the team at {Company} remains dedicated to ensuring that it meets the highest standards of quality, safety, and efficacy. With the potential to transform the way certain medical conditions are diagnosed and treated, the prototype represents a significant step forward in the quest to improve patient care and outcomes.In conclusion, {Company}'s medical device prototype is a remarkable achievement that has the potential to revolutionize healthcare. With its innovative design, advanced functionality, and broad applications, the prototype is set to make a significant impact on the way medical conditions are diagnosed and treated. As {Company} continues to drive innovation in the field of medical technology, it is clear that the future of healthcare is in good hands.